Magnetic Fenton Package System for Pharmaceutical Wastewater

Fenton reaction: Under acidic conditions, H202 reacts with Fe2+to produce hydroxyl radicals, which can rapidly oxidize and decompose recalcitrant organic compounds.

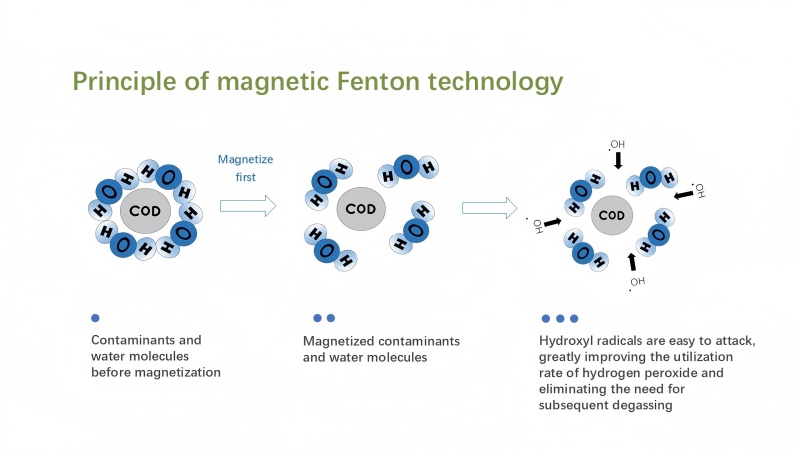

Our Magnetic Fenton Package System magnetize water molecules to rearrange them in the direction of magnetic field lines, greatly increasing the efficiency of hydroxyl radical oxidation and decomposition of COD. This can decompose most difficult to degrade organic compounds into carbon dioxide, water, and simple organic compounds

Waste water flow:

20,000m3/dayNumber of Reaction Tower:

2 setsCOD Removal:

120mg/L to 40mg/L98% H2S04 Consumption:

250mg/LFeS04 Consumption:

300mg/L27.5% H2O2 Consumption:

220mg/L30% NaOH Consumption:

600mg/L

Why choose Magnetic Fenton Process

Low Power Consumption

1. The reactor has a lower height, requiring feed pumps with lower head, resulting in reduced power consumption.2. It operates without media, eliminating the need for recirculation pumps/air compressors and saving electrical

energy.

3. No degassing is required in the stabilization basin, further reducing power consumption.

4. Sludge production is lower, leading to decreased power consumption for sludge dewatering.

Low Civil Construction Cost

Traditional Fenton / Fluidized Bed Fenton: The hydraulic retention time in the oxidation reaction tank istypically 2-4 hours.

Magnetic Fenton: The required retention time is only 1 hour. For a treatment capacity of 10,000 m'/day,this can save at least 500 m3 of tank volume.Eliminates the need for a crystal storage yard, saving approximately 50 m3 of footprint for a 10,000 m'/daywater.

-

Why choose Magnetic Fenton Process

Fully Automatic running

1. One-Button Start/Stop & Fully Automated Operation

2. Unmanned Operation & Staff Can Perform Concurrent Duties

3. Simple Operation: Requires only basic electrical knowledge for routine operation.

4. Linear Chemical Dosage Adjustment (Optional): Automatically adjusts chemical consumption basedon fluctuations in the influent COD concentration.

Magnetic Fenton: Can be started and stopped at any time without incurring downtime losses.

Low Failure Rate

Magnetic Fenton eliminates the need for several components (such as media, recirculation pumps, aircompressors), thereby avoiding all the common failures mentioned above. The system failure rate is significantlyreduced, with zero reactor failures, achieving a capacity utilization rate of nearly 100%. It prevents faults thatcould disrupt the normal operation of the wastewater treatment plant.

-

Advantage of Magnetic Fenton Process

-

Comparison between three generation of Fenton Process

| Items | Traditional Fenton | Fluidized Bed Fenton | Purevita Magnetic fenton | |

| Treatment traget | CODcr | Reduce from 120 mg/L to 50 mg/L | ||

| Chemical consumption | 98% H2SO4 | 450 mg/L | 350mg/L | 250mg/L |

| FeSO4 | 900 mg/L | 400mg/L | 300mg/L | |

| 27.5% H2O2 | 600 mg/L | 450mg/L | 220mg/L | |

| 30% NaOH | 1000 mg/L | 800mg/L | 600mg/L | |

| Filler/Catalyst | No request | Request to use and replace regularly | No request, no clumping or clogging issue | |

| Main Chemical cost | 0.38 usd/ton | 0.27 USD/ton | 0.18 USD/ton | |

| Sludge amount(per 10,000m3 waste water) | 3-4 ton | 2-2.5 ton Absolute dry sludge | <1.5 ton Absolute dry sludge | |

| Energy Consumption | Cost (calculated by 0.09usd/kwh) | 0.005 usd/ton | 0.0025usd/ton | 0.007usd/ton |

| Civil construction | Residence time (calculated in reaction degassing neutralization tank) | 3-5 hours | 2 hours | 1 hour |

| Reaction pool volume (per 10,000m3 waste water) |

1500-2500m³ | 1000m³ | 500m³ | |