Salt Water Type PLC Control Sodium Hypochlorite Generator for Drinking Water Plant

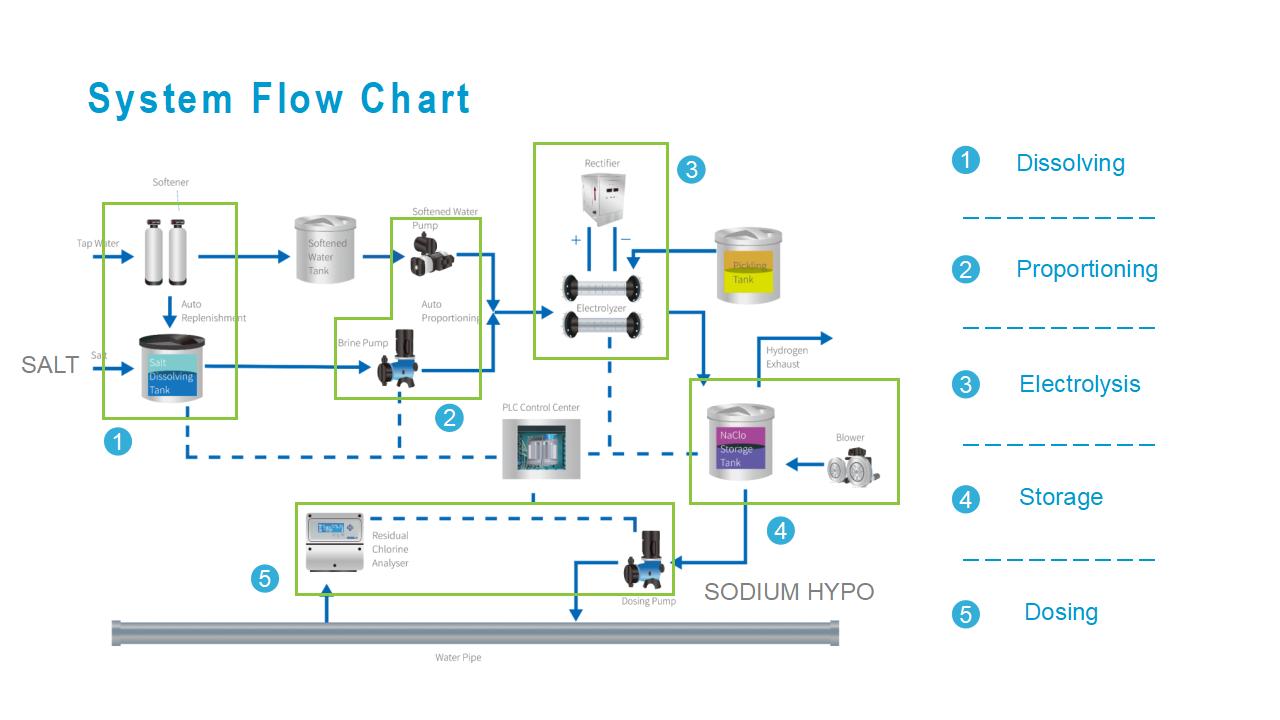

Purevita's unique salt water electrolysis technology offers an eco-friendly, safe and economical solution for water disinfection. Using only salt, water, and electricity, our customized electrolytic cells produce sodium hypochlorite on site and on demand, eliminating the need for transporting hazardous chemicals.

Capacity:

10kg/hOutput Flow:

1250L/hControl:

PLC control/full automaticChlorine concentration:

8000ppmAdditive:

SaltSalt Consumption:

3.5kg/hr per cl2Power Consumption:

4kw/hr per cl2Application:

Drinking water treatmentSalt Water Type Sodium Hypochlorite Generator for Drinking Water Plant

Purevita Sodium Hypochlorite Generator

Salt Water Type PLC Control Sodium Hypochlorite Generator for Drinking Water Plant utilize electrolysis to generate sodium hypochlorite from brine, resulting in a solution with a concentration of 0.8%. This low-concentration sodium hypochlorite offers several distinct advantages:

Stability and Longevity:

Unlike conventional sodium hypochlorite solutions that can lose up to 20% of their chlorine content during storage, Purevita’s solution remains stable over months without requiring additives. This stability ensures consistent chlorine levels for effective disinfection.

Safety and Operational Efficiency:

Produced in close proximity to the process, the direct storage and dosing of sodium hypochlorite by Purevita systems minimize the risk of accidental spillage and exposure to operating personnel, enhancing overall safety protocols.

Main Features:

Raw Materials: Utilizes only salt or seawater, which are safe and convenient for transportation and storage, without volatility or toxicity concerns.

Electrode Connection: Employs a bipolar electrode connection mode, minimizing heat generation and reducing sodium hypochlorite salt and power consumption.

Efficiency Standards:

Salt consumption < 3.5kg / kg Cl2

AC Power consumption < 4kw / kg Cl2

Control System: Equipped with Siemens PLC and touch screen for full automatic control, ensuring operational precision and ease of use.

Longevity: Extended lifespan of critical components:

These features collectively make sodium hypochlorite disinfection a robust choice for water treatment facilities seeking effective, safe, and sustainable disinfection solutions.

| GTL-5000 | GTL-8000 | GTL-10000 | GTL-15000 | GTL-20000 | |

|---|---|---|---|---|---|

| Chlorine Capacity | 5Kg/hr | 8Kg/hr | 10Kg/hr | 15Kg/hr | 20Kg/hr |

| Water treatment Capacity(At 1ppm dosing) | 100mld | 160MLD | 200MLD | 300MLD | 400MLD |

| Salt Consumption | 3.5kg/kg Cl2 | 3.5kg/kg Cl2 | 3.5kg/kg Cl2 | 3.5kg/kg Cl2 | 3.5kg/kg Cl2 |

| Power Consumption | 4.0kw/ kg Cl2 | 4.0kw/ kg Cl2 | 4.0kw/ kg Cl2 | 4.0kw/ kg Cl2 | 4.0kw/ kg Cl2 |

| Concentration of HYPO | 5000~8000ppm | 5000~8000ppm | 5000~8000ppm | 5000~8000ppm | 5000~8000ppm |

| Production Flow Rate | 625~1000 L/hr | 1000~1600L/hr | 1250~2000L/hr | 1875~3000L/hr | 2500~4000L/hr |

Advantage

Eliminate delivery & handling of hazardous chemicals

Handle only salt

Generate on site for on-demand or residual storage

No exhaust gases as with conventional sodium hypochlorite solutions in dosing pumps

Eliminate injection point scaling associated with commercial sodium and calcium hypochlorite

Considerable Health & Safety benefit to operators

Applications