COD Removal Magnetic Fenton Package System for Industrial Waste Water Treatment

Fenton reaction: Under acidic conditions, H202 reacts with Fe2+to produce hydroxyl radicals, which can rapidly oxidize and decompose recalcitrant organic compounds.

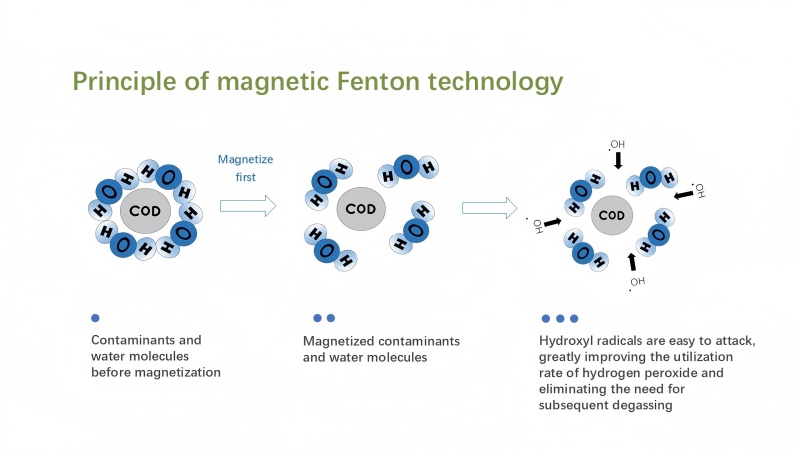

Our Magnetic Fenton Package System magnetize water molecules to rearrange them in the direction of magnetic field lines, greatly increasing the efficiency of hydroxyl radical oxidation and decomposition of COD. This can decompose most difficult to degrade organic compounds into carbon dioxide, water, and simple organic compounds

Waste water flow:

20,000m3/dayNumber of Reaction Tower:

2 setsCOD Removal:

120mg/L to 40mg/L98% H2S04 Consumption:

250mg/LFeS04 Consumption:

300mg/L27.5% H2O2 Consumption:

220mg/L30% NaOH Consumption:

600mg/L

Chemical process principle of Fenton

Under acidic conditions, H2O2 reacts with Fe2+ to produce hydroxyl radicals, which have strong oxidizing ability to quick oxidize and decompose the organic matter which is difficult to degrade.

Reaction equation: H202+Fe2+ →Fe3++OH-+·OH

Fe2+ is catalyst, H202 is oxidant, ·OH is hydroxyl radical, and the amount of hydroxyl radical generation is determined by Fe2+ and H202. Fenton’s key point is the oxidizing ability of hydroxyl radicals, which have two path after they are produced:

1. It does not contact pollutants and decomposes naturally, causing waste;

2. Contact to pollutants and oxidation.

Improving the oxidation efficiency of hydroxyl radicals is the R&D direction of all Fenton process manufacturers.

-

How do we improve oxidation efficiency

When waste water passes through the magnetic field area at a certain flow rate, the paramagnetic water molecules are rearranged according to the direction of the magnetic field lines, thus changing the binding state of dissolved and colloidal organic pollutants and water molecules in the waste water, and balance of water molecular groups is broken. Thus increases the probability of collision between pollutants and hydroxyl radicals, significantly increasing the speed and extent of chemical reactions.

Magneto Fenton Process use fixed-point removal method to oxidize COD , H202 consumption is extremely low, 40% cheaper than traditional Fenton.

Firstly magnetize the wastewater, change the arrangement position between pollutant molecules and water molecules, so that hydroxyl radicals can easily contact COD

-

Advantage of Magnetic Fenton Process

-

Comparison between three generation of Fenton Process

| Items | Traditional Fenton | Fluidized Bed Fenton | Purevita Magnetic fenton | |

| Treatment traget | CODcr | Reduce from 120 mg/L to 50 mg/L | ||

| Chemical consumption | 98% H2SO4 | 450 mg/L | 350mg/L | 250mg/L |

| FeSO4 | 900 mg/L | 400mg/L | 300mg/L | |

| 27.5% H2O2 | 600 mg/L | 450mg/L | 220mg/L | |

| 30% NaOH | 1000 mg/L | 800mg/L | 600mg/L | |

| Filler/Catalyst | No request | Request to use and replace regularly | No request, no clumping or clogging issue | |

| Main Chemical cost | 0.38 usd/ton | 0.27 USD/ton | 0.18 USD/ton | |

| Sludge amount(per 10,000m3 waste water) | 3-4 ton | 2-2.5 ton Absolute dry sludge | <1.5 ton Absolute dry sludge | |

| Energy Consumption | Cost (calculated by 0.09usd/kwh) | 0.005 usd/ton | 0.0025usd/ton | 0.007usd/ton |

| Civil construction | Residence time (calculated in reaction degassing neutralization tank) | 3-5 hours | 2 hours | 1 hour |

| Reaction pool volume (per 10,000m3 waste water) |

1500-2500m³ | 1000m³ | 500m³ | |