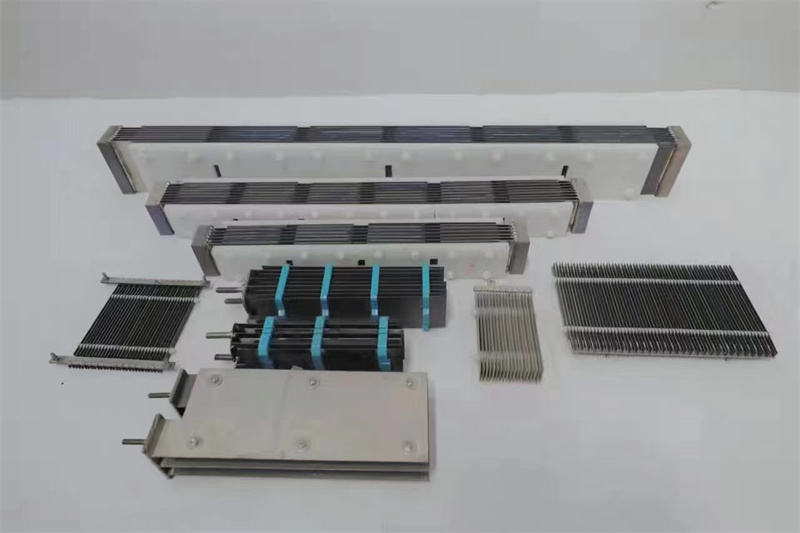

Ruthenium Iridium coating Pure Titanium Electrode For Water Treatement

Coating titanium anode is also referred to as Mixed Metal Oxide (MMO) titanium anode and Dimensionally Stable Anode (DSA), as well as Dimensionally Stable Electrode (DSE).

By brushing precious metal coating on the titanium substrate, it can have a good electric catalytic activity and electrical conductivity.

Chlorine Production:

100g/hInput current:

30-40AInput Voltage:

14~16VCoating:

Ru+IrDimension:

CustomizedCoating Thickness:

1~10 UmPH level:

1~14life time:

3~5years

Introduction:

Titanium anode is remarkable for its stability in size, which guarantees that the distances between electrolytic electrodes remain unchanged during production. Besides, it requires lower operating voltage and power consumption than other electrodes, reducing electric power consumption by 10~20%.

In addition, titanium anode exhibits superior anti-corrosion capability and a long working life, as well as can overcome graphite and lead anode dissolution in electrolyte, ensuring electrolytic product won't be contaminated. With a high current density, small overpotential and excellent catalytic activity, the titanium anode could effectively enhance production efficiency, and avoid short circuit of lead anode after deformation. It also stands out for its easy shaping and high degree of refinement, and the titanium substrate can be recycled for reuse. Furthermore, its lower overpotential allows for the surface of electrodes and electrode bubbles to be easily excluded, thus efficiently lowering the voltage of electrolytic cells.

This product's surface is evenly coated in black and highly durable. It boasts low chlorine-evolution potential, a long service life, and high current efficiency. The DC current range is between 2000A/㎡ and 10000A/㎡. Its working temperature range is from 25℃ to 80℃. Different metal coatings are available, such as Ruthenium, Ruthenium plus Iridium, Ruthenium plus Iridium plus Tin, and Rare earth plus Ruthenium. The coating thickness can be between 2μm and 10μm depending on the amount of Ruthenium used, which ranges from 8g/㎡ to 35g/㎡. It's suitable for working in an environment of PH 0-14, in temperatures of up to 100℃, or even in seawater without being affected by corrosion.

Technical Parameters:

| Capacity | Flange diameter | Cell Diameter | Length | Input Current | Input Voltage | Inlet&outlet Diameter | Flow |

| 50g/h | 140mm | 80mm | 420mm | 30-40A | 7-8V | 32.3mm | 7-10L/H |

| 100g/h | 140mm | 80mm | 670mm | 30-40A | 14-16V | 32.3mm | 12-20L/H |

| 200g/h | 170mm | 110mm | 670mm | 60-80A | 14-16V | 32.3mm | 25-40L/H |

| 350g/h | 200mm | 130mm | 670mm | 90-120A | 14-16V | 32.3mm | 45-70L/H |

| 500g/h | 200mm | 140mm | 760mm | 90-130A | 21-24V | 32.3mm | 62-100L/H |

| 800g/h | 240mm | 160mm | 970mm | 120-160A | 28-32V | 63.3mm | 100-160L/H |

| 1000g/h | 240mm | 160mm | 970mm | 135-180A | 28-32V | 63.3mm | 125-200L/H |

| 1500g/h | 240mm | 160mm | 1390mm | 280-360A | 21-24V | 63.3mm | 160-260L/H |

| 2000g/h | 240mm | 160mm | 1780mm | 280-360A | 38-32V | 63.3mm | 210-340L/H |

| 3000g/h | 240mm | 190mm | 1780mm | 400-500A | 28-32V | 63.3mm | 320-520L/H |

| 4000g/h | 310mm | 230mm | 2130mm | 520-700A | 28-32V | 110.6mm | 500-800L/H |

| 5000g/h | 310mm | 230mm | 2130mm | 650-800A | 28-32V | 110.6mm | 650-1000L/H |

Manufacturing Process