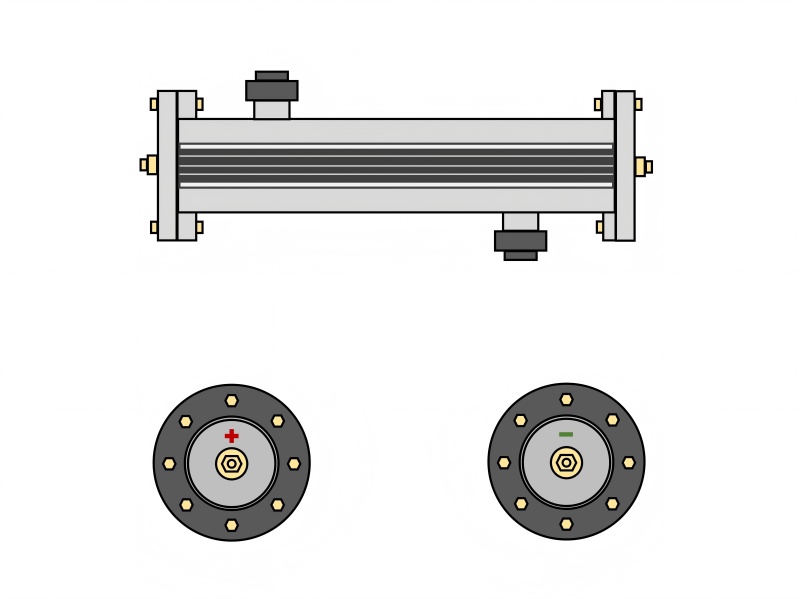

1kg/h Ruthenium-Iridium coating Titanium Electrolytic cell

The polarity reverse titanium electrolytic cell is utilized in sodium hypochlorite generators. Sodium hypochlorite solution is produced by electrolyzing a sodium chloride solution without a membrane and then diluting it. This technology is suitable for various applications including sodium hypochlorite generators, water treatment equipment, and electrolytic disinfection equipment.

Chlorine Production:

1kg/hInput current:

125-200AInput Voltage:

28~32VCoating:

Ru-IrDimension:

CustomizedCoating Thickness:

1~10 UmPH level:

1~14life time:

2~5years

Product Description:

Design Features

1kg/h Ruthenium-Iridium coating Titanium Electrolytic cell features a tubular cell design with multiple built-in polar chambers. This design has a compact structure in each polar chamber, which helps disperse the influence of stray currents during electrolysis and significantly improves the electrolysis efficiency. Additionally, it has a plate-type bipolar structure electrode group and an optimized electrode plate coating formula.

The electrode coating is a nano-scale refined grain ruthenium-iridium mixed oxide coating suitable for the chlorine evolution environment. This coating has stronger corrosion resistance and a longer service life.

Technical Parameters:

| Parameters | Details |

|---|---|

| Appearance | Customized |

| Production | Sodium Hypochlorite |

| Chlorine output | 1kg/h |

| Size | Customized |

| Application | Water Treatment |

| Electrolyte | Brine/sea Water |

| Input voltage | 28~32V |

| Content of noble metal | 10g/m2-50g/m2 |

| Coating thickness | 1~10 Um |

| Input current | 125-200A |

| Coating | Ru-Ir |

| Titanium electrode type | Tubular cell, plate electrode |

Manufacturing Process

1. Production and preparation of sodium hypochlorite disinfection solution

2. Industrial wastewater treatment

3. Tap water treatment

4. Municipal sewage treatment

5. Breeding and livestock disinfection treatment

6. Other occasions requiring disinfection