0.8% Concentration On-site Sodium Hypochlorite Generator for Power Plant

On-site generation of chlorine disinfectants offers a safe, cost-effective, and efficient water treatment solution. Suitable for diverse applications—from potable water purification to cooling tower microbiological control—it enables the production of disinfectant precisely when and where it's needed.

0.8% Concentration On-site Sodium Hypochlorite Generator for Power Plant

Brief Introduction

0.8% Concentration On-site Sodium Hypochlorite Generator for Power Plant generates a 0.8 % sodium hypochlorite solution through the electrolysis of brine, consuming only water, salt and electricity. By producing hypochlorite on-site and on-demand, the system eliminates concerns associated with transportation and storage of chlorine gas or commercial sodium hypochlorite solutions, making it ideal for any medium to large scale application requiring chlorination.

Sodium hypochlorite turn into hypochlorous acid by hydrolysis in water, and turn into nascent oxygen [O] in further step, which having ultra strong oxidation to effect the protein of thalli and virus, and terminate pathogenic microorganisms. Besides that, during the reaction of hypochlorous acid, it’s not only having effects on cell wall and viral coat, but due to its small volume and no electrical charge, it’s also permeate into germ or virus generate oxidation reaction with the organic polymer like protein, nucleic acid and enzyme, and thus to kill pathogenic microbes. What’s more, the chlorine ion generated by hypochlorous acid will change the osmotic pressure significantly, cause death of cell by lost of activity.

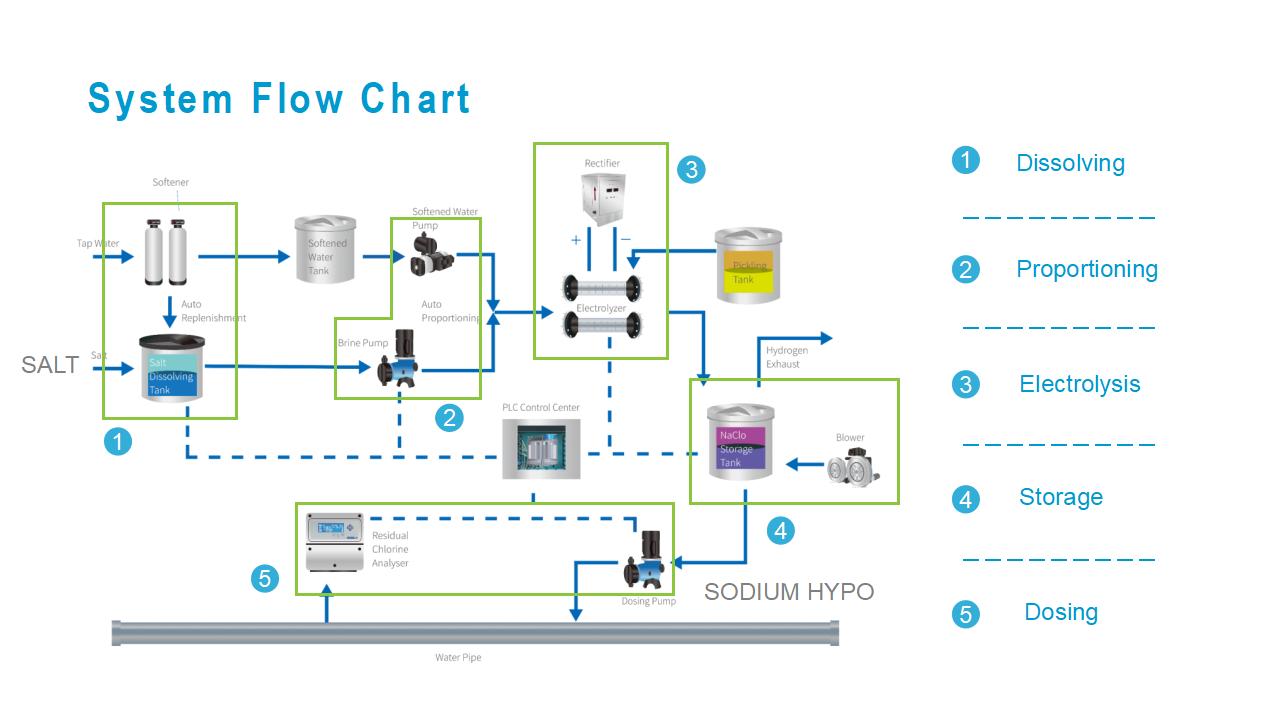

1. Influent water passes through a water softener to reduce hardness therefore reducing the scaling of electrodes and lengthening the cleaning time

2. Salt is dissolved by softened water into saturated brine in the tank.

3. The saturated brine will be diluted into 2.5%-3%, then pass through the electrolytic cell and finally be electrolyzed into 0.8% solution of sodium hypochlorite.

4. The 0.8% hypochlorite solution flows into a storage tank. Hydrogen, the only byproduct of the process, is safely vented to the atmosphere.

5. Accuracy liquid dosed and controlled by residual chlorine analyser

--------------占位---------------

Specifications

| Model | GTL-5000 | GTL-8000 | GTL-10000 | GTL-15000 | GTL-20000 | GTL-40000 |

| Available chlorine(kg/h) | 5 | 8 | 10 | 15 | 20 | 40 |

| NaClO Output flow(L/h) | 625 | 1000 | 1250 | 1875 | 2500 | 5000 |

| NaClO concentration(mg/L) | 8000 | 8000 | 8000 | 8000 | 8000 | 8000 |

| Power supply(kw) | 30 | 48 | 60 | 90 | 120 | 240 |

| Voltage | 380V/50hz three phase | 380V/50hz three phase | 380V/50hz three phase | 380V/50hz three phase | 380V/50hz three phase | 380V/50hz three phase |

| Feed brine concentration | 2.5~3% | 2.5~3% | 2.5~3% | 2.5~3% | 2.5~3% | 2.5~3% |

| Feed Salt requirement | 99.3% food grade salt | 99.3% food grade salt | 99.3% food grade salt | 99.3% food grade salt | 99.3% food grade salt | 99.3% food grade salt |

| Feed water flow | 625 | 1000 | 1250 | 1875 | 2500 | 5000 |

| Feed water requirement | tap water | tap water | tap water | tap water | tap water | tap water |

| Salt Consumption(kg/h) | 17.5 | 28 | 35 | 52.5 | 70 | 140 |

| AC Power consumption(kwh) | 22.5 | 36 | 45 | 67.5 | 90 | 180 |

| Cell arrangement | Horizontal | Horizontal | Horizontal | Horizontal | Horizontal | Horizontal |

| H2 production amount(m3/h) | 1.75 | 2.8 | 3.5 | 5.25 | 7 | 14 |

| Number of Cell (pcs) | 2 | 2 | 2 | 3 | 4 | 4 |

| Operation pressure(bar) | 2~4 | 2~4 | 2~4 | 2~4 | 2~4 | 2~4 |

| Feed water temperature | 15~25℃ | 15~25℃ | 15~25℃ | 15~25℃ | 15~25℃ | 15~25℃ |

| Cleaning mode | Acid washing | Acid washing | Acid washing | Acid washing | Acid washing | Acid washing |

-