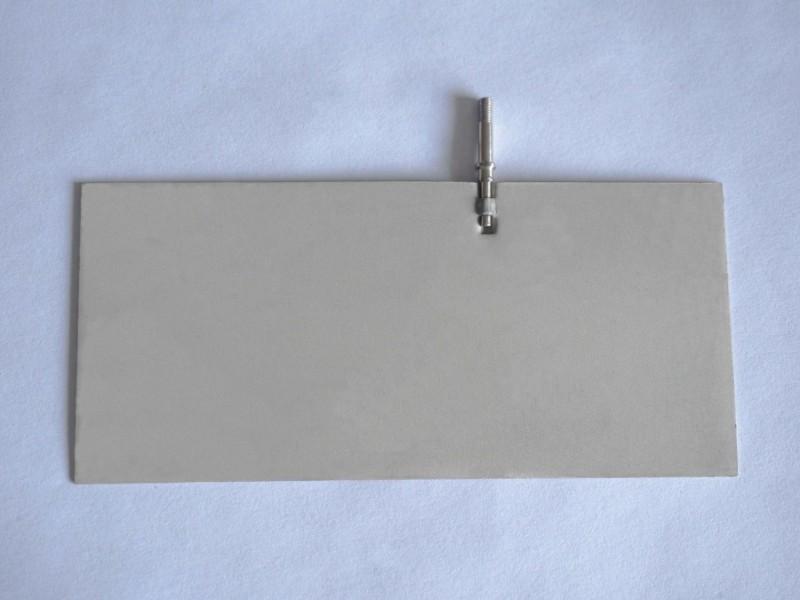

Platinum coating Pure Titanium Dimensionally Stable Anode

Platinum-coated titanium electrode is a typical Dimensionally Stable Anode. It is a composite electrode constructed with a metallic titanium substrate as the base, upon which a thin layer of platinum (often not pure platinum but rather an alloy or mixture of platinum and other precious metals) serving as the active catalytic layer is applied onto its surface through specialized processes such as thermal decomposition or electroplating.

Chlorine Production:

CustomizedInput current:

CustomizedInput Voltage:

CustomizedCoating:

PlatinumDimension:

CustomizedCoating Thickness:

CustomizedPH level:

1~14life time:

20 years

Core Structure:

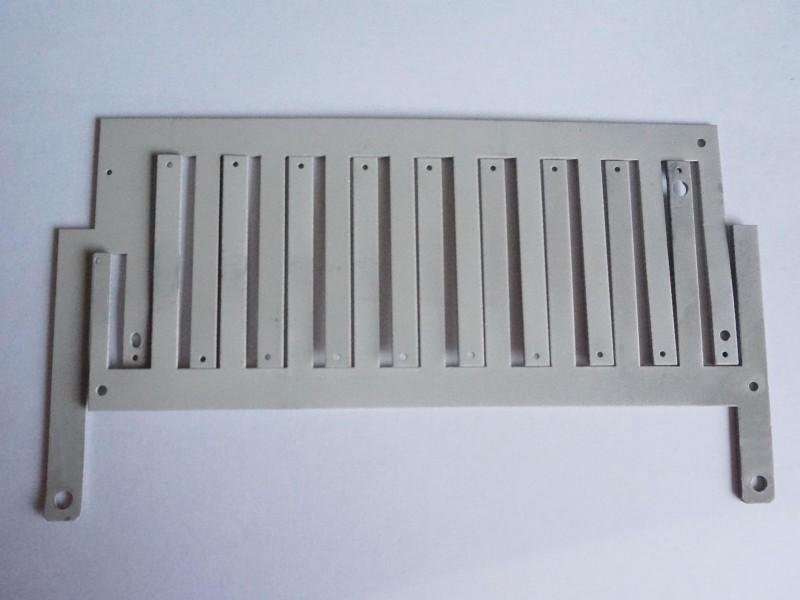

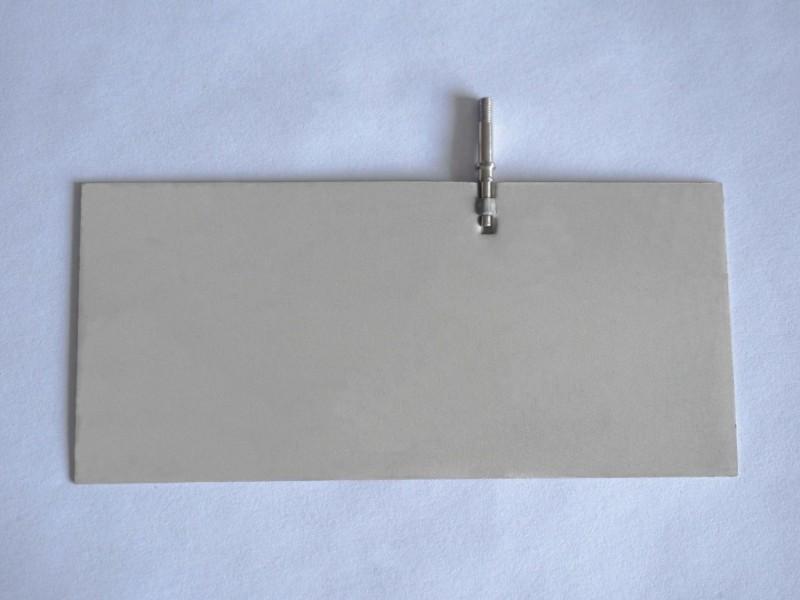

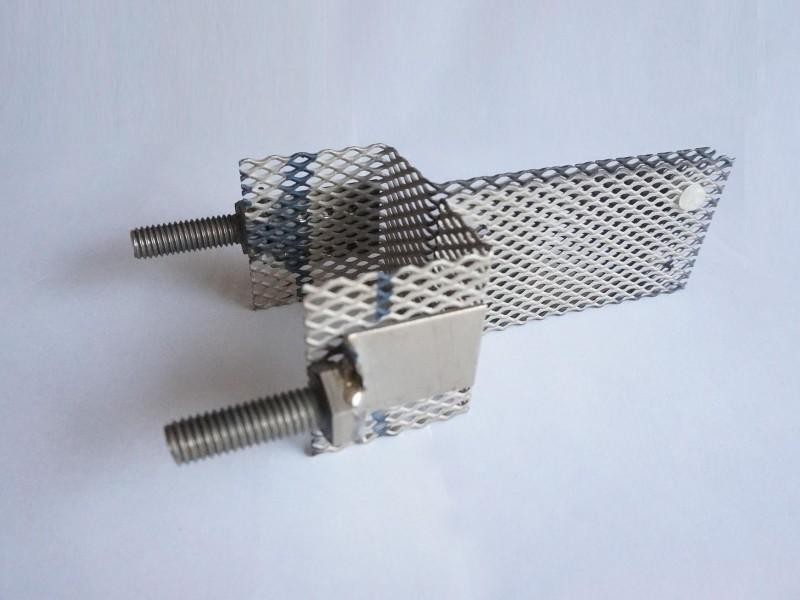

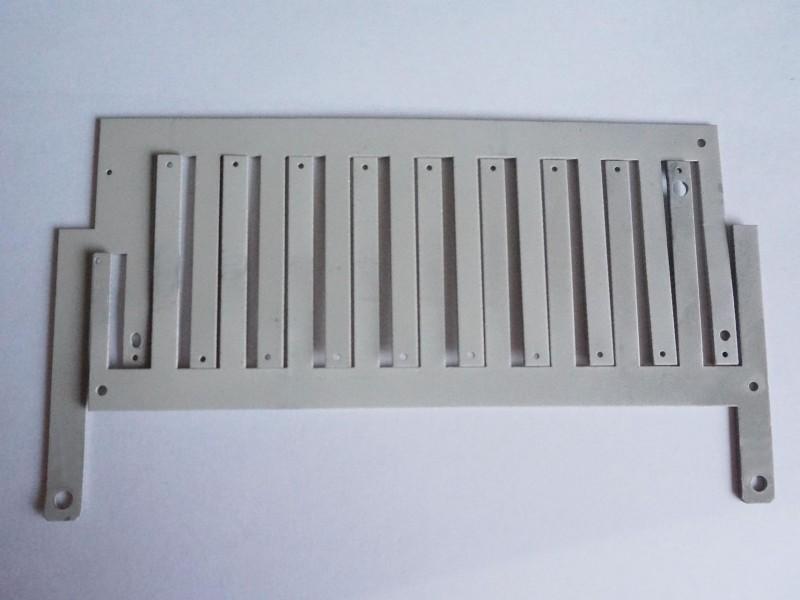

Titanium Substrate: Serves as the backbone of the electrode, providing mechanical strength, electrical conductivity, and specific geometries (e.g., mesh, plate, rod). A key advantage of titanium lies in the formation of a dense passive film on its surface, which protects the substrate from corrosion during anodic polarization.

Platinum Coating: Acts as the active surface where electrochemical reactions occur, delivering exceptional electrocatalytic activity and chemical stability.

This product's surface is evenly coated in black and highly durable. It boasts low chlorine-evolution potential, a long service life, and high current efficiency. The DC current range is between 2000A/㎡ and 10000A/㎡. Its working temperature range is from 25℃ to 80℃. Different metal coatings are available, such as Ruthenium, Ruthenium plus Iridium, Ruthenium plus Iridium plus Tin, and Rare earth plus Ruthenium. The coating thickness can be between 2μm and 10μm depending on the amount of Ruthenium used, which ranges from 8g/㎡ to 35g/㎡. It's suitable for working in an environment of PH 0-14, in temperatures of up to 100℃, or even in seawater without being affected by corrosion.

Advantage

--------------占位---------------

Manufacturing Process