Medium Pressure Closed Vessel Ultraviolet System for waste water

Medium-pressure ultraviolet disinfection equipment is a high-tech product developed by Purevita based on many years of disinfection experience and combined with a number of large and medium-sized municipal water disinfection and swimming pool water disinfection experiences, jointly developed by professors of various disciplines, design engineers, and on-site operators. The L-shaped appearance structure is more optimized than the conventional cross-shaped structure, and the ultraviolet utilization rate is higher.

Water flow:

10,000m3/dayNumber of Lamps:

24~32Number of Modules:

4 setsTotal Power:

10kwLow Pressure Open Channel UV System for waste water plant

Brief Introduction

The sewage treated by the Low Pressure Open Channel UV System for waste water plant passes through the UV system module arranged in the slotted ditch to sterilize and disinfect the water flowing through the ditch, thereby solving the problem of excessive bacteria indicators in the treated sewage. The open channel ultraviolet disinfection system has a fast sterilization speed, good effect, high sterilization efficiency, low operating cost , and no secondary pollution caused by disinfection .

Optimized for hydraulic performance, this design ensures uniform flow, minimal head loss, and consistent UV dose distribution, guaranteeing high disinfection efficiency under varying conditions. Modular scalability makes it ideal for new installations or retrofits.

Our Proprietary Technologies

1. Parallel Central Drive Cleaning Technology – Eliminates quartz sleeve cracking caused by unilateral force in traditional single-drive systems.

2. Adaptive Flexible Cleaning Ring Technology – Resolves sleeve “jamming” due to temperature variations. A dual-thickness cleaning ring design eliminates dead zones and ensures thorough cleaning. Double-layer rings enhance quartz sleeve maintenance.

3. Passive Flow-Controlled Flap Gate Technology – Automatically adjusts channel water levels based on flow rate. An electric closed-loop control system maintains optimal disinfection channel height for consistent efficacy.

Specification of UV System

Light Source: Low-Pressure Mercury Amalgam Lamps

Light Source: Low-Pressure Mercury Amalgam Lamps

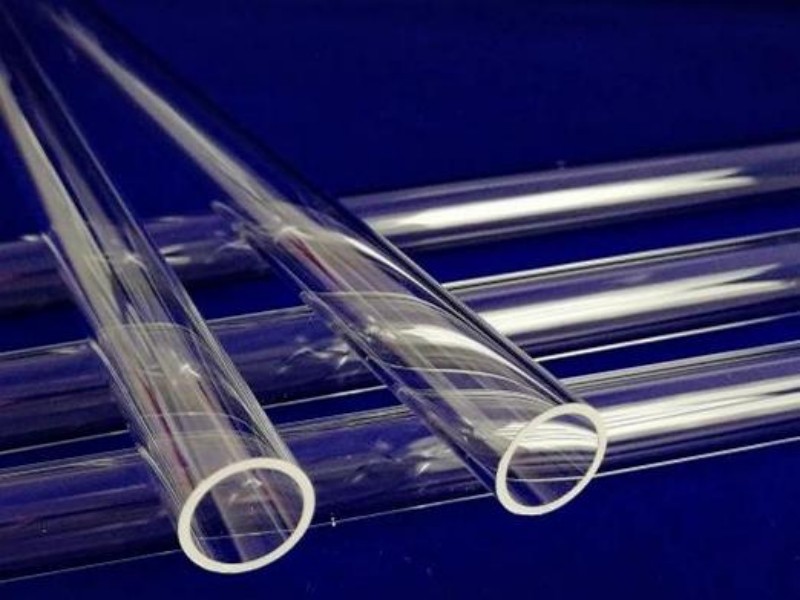

Quartz Sleeves

Quartz Sleeves

Control Cabinet

Control Cabinet