Titanium Sodium Hypochlorite Electrolytic Cell For Producing 0.8% Sodium Hypochlorite Liquid From Brine

Electrolyser(electrodes or electrolysis cell) is designed for producing 8000ppm sodium hypochlorite through 0.3% brine, which is stable and safty running onsite.

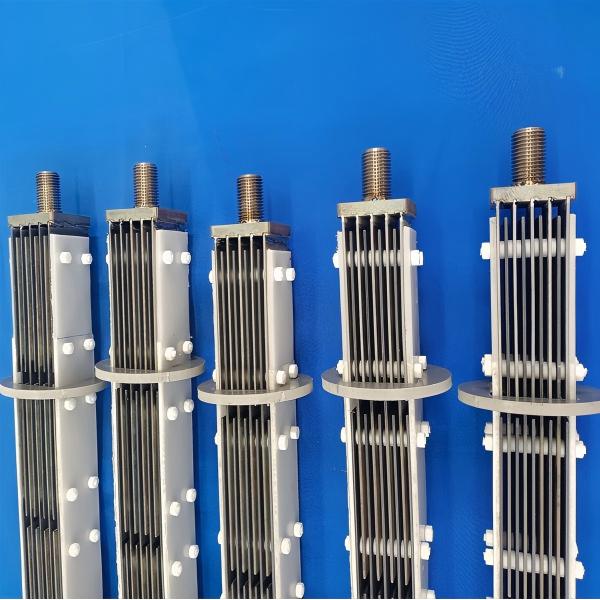

The electrodes is made of pure Titanium, with ruthenium & iridium oxide coating which ensure over 5 years coating life, over 18 years titanium base material, reduce the chlorine evolution potential and electricity consumption.

Chlorine Production:

500g/hInput current:

90-130AInput Voltage:

21~24VCoating:

Ru+IrDimension:

CustomizedCoating Thickness:

1~10 UmPH level:

1~14life time:

3~5years

Introduction:

Electrolytic cell is the most important part for chlorination system, it is key component of generating sodium hypochlorite solution by brine electrolysis.

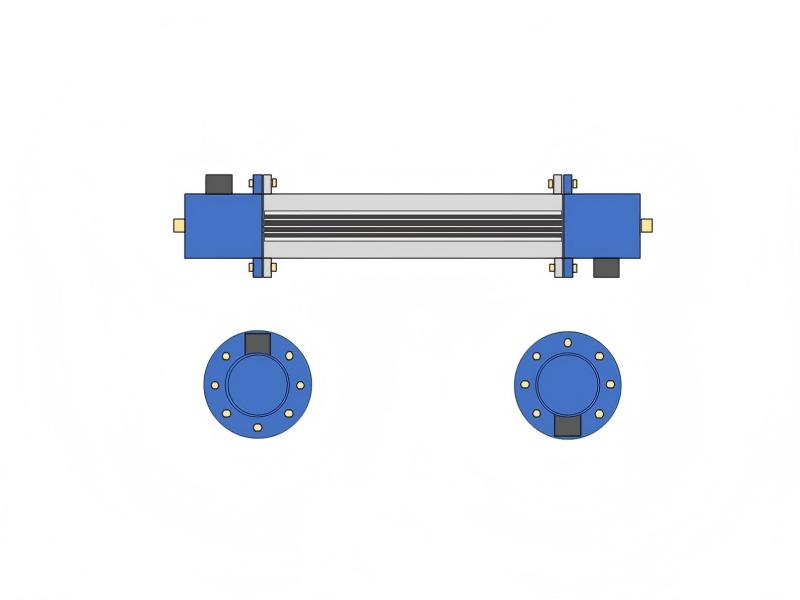

Electrolytic cell consist of cell body and electrolysis electrode.

Advantages of coated titanium electrode

1. The anode size is stable, and the distance between the electrodes does not change during the electrolysis process.

2. Low operating voltage, low power consumption, dc power consumption can be reduced by 10-20%.

3. Titanium anode has long working life and strong corrosion resistance.

4. The dissolution of graphite anode and lead anode can be overcome, and the electrolyte and cathode products can be avoided.

5. High current density, low overpotential, high catalytic activity of electrode, high efficiency.

6. In the production of chlor-alkali, titanium anode is used with high quality, high purity of chlorine gas, no CO2, and high alkali concentration, which can save steam for heating and energy consumption.

7. It can avoid short circuit problem after lead anode deformation and improve current efficiency.

8. The shape is easy to make and high precision.

9. Titanium matrix can be reused.

10. With low overpotential, the air bubbles between the electrodes and the electrodes can be removed easily and the electrolytic cell electricity can be reduced effectively

This electrode has three outstanding advantages in the chlor-alkali production industry, especially the electrolytic production of sodium hypochlorite.

1. low electric potential for chlorine separation

In the production of sodium hypochlorite, the electric potential determines the voltage at the working end, the lower electric potential means a lower operating voltage, lower energy consumption, and less oxygen during electrolysis, increasing the electrolysis efficiency.

2. Low energy consumption in electrolysis

The chlorine electrolysis reaction will inevitably has side reaction, like OH-electrolysis into oxygen. Due to the low electric potential in our electrode, chlorine electrolysis is prioritized, and excellent process improves the electrode sheet heating phenomenon. The operating voltage is low, power consumption is small, and DC power consumption is 10% 20% lower, compared to other products.

3. longer service life

Each batch of electrode will be regularly tested the service life. The average life of this series of electrodes is more than 15,000 hours, 20% higher than similar products.

Technical Parameters:

| Capacity | Flange diameter | Cell Diameter | Length | Input Current | Input Voltage | Inlet&outlet Diameter | Flow |

| 50g/h | 140mm | 80mm | 420mm | 30-40A | 7-8V | 32.3mm | 7-10L/H |

| 100g/h | 140mm | 80mm | 670mm | 30-40A | 14-16V | 32.3mm | 12-20L/H |

| 200g/h | 170mm | 110mm | 670mm | 60-80A | 14-16V | 32.3mm | 25-40L/H |

| 350g/h | 200mm | 130mm | 670mm | 90-120A | 14-16V | 32.3mm | 45-70L/H |

| 500g/h | 200mm | 140mm | 760mm | 90-130A | 21-24V | 32.3mm | 62-100L/H |

| 800g/h | 240mm | 160mm | 970mm | 120-160A | 28-32V | 63.3mm | 100-160L/H |

| 1000g/h | 240mm | 160mm | 970mm | 135-180A | 28-32V | 63.3mm | 125-200L/H |

| 1500g/h | 240mm | 160mm | 1390mm | 280-360A | 21-24V | 63.3mm | 160-260L/H |

| 2000g/h | 240mm | 160mm | 1780mm | 280-360A | 38-32V | 63.3mm | 210-340L/H |

| 3000g/h | 240mm | 190mm | 1780mm | 400-500A | 28-32V | 63.3mm | 320-520L/H |

| 4000g/h | 310mm | 230mm | 2130mm | 520-700A | 28-32V | 110.6mm | 500-800L/H |

| 5000g/h | 310mm | 230mm | 2130mm | 650-800A | 28-32V | 110.6mm | 650-1000L/H |

Manufacturing Process

1. Production and preparation of sodium hypochlorite disinfection solution

2. Industrial wastewater treatment

3. Tap water treatment

4. Municipal sewage treatment

5. Breeding and livestock disinfection treatment

6. Other occasions requiring disinfection