Sea Water Electrolysis Sodium Hypochlorite Generator for Cooling Tower

Sea Water Electrolysis Sodium Hypochlorite Generator is used electrolytic principle, it works through by on-site electrolysis of seawater to produce sodium hypochlorite solution, and automatically dosing into the feed seawater to eliminate algae and microorganisms, thus prevent the biofouling in the seawater system (such as cooling circuits, intake pipes and heat exchangers).

Capacity:

10kg/hOutput Flow:

5000L/hControl:

Automatic controlChlorine concentration:

2000ppmAdditive:

Sea waterSalt Consumption:

-Power Consumption:

4.5kw/kg Cl2Application:

Power plant, cooling tower, sea water farmingSea Water Electrolysis Sodium Hypochlorite Generator for Cooling Tower

Working Principle

Sea Water Electrolysis Sodium Hypochlorite Generator for Cooling Tower is generating sodium hypochlorite through the electrolysis of seawater is a cost-effective and safe method to eliminate algae and microorganisms and prevent the biofouling. Sodium hypochlorite is a versatile oxidizing agent that can be generated and used on-site.

• Basic reactions occurring in the electrolytic cell:

At the anode, chlorine gas is evolved:

2Cl- = Cl2 + 2e- _________________ ①

At the cathode, hydrogen gas is evolved:

2H+ + 2e- = H2 __________________ ②

The Cl2 evolved at the anode dissolves in the electrolyte to form HCl and HOCl. Since there is no membrane between the anode and the cathode, the H2 evolved at the cathode and generates OH-, which combines with the H+ produced by dissociation to form H2O and NaOCl, thus completing the homogeneous secondary chemical reaction. The overall reaction is:

NaCl + H2O → NaOCl + H2

Industrial Biofouling Control

Seawater Electrolysis Sodium Hypochlorite Generator are a reliable and economic solution for industrial biofouling control. The electrochlorination process is simple and straight forward, combining three common consumables (salt(sea water), water and electricity) to generate a disinfecting agent. SANILEC systems can be provided in any capacity to meet customer and application-specific needs.

On-site generation of sodium hypochlorite is an economical and safe method to produce a powerful biocide and disinfecting agent for use in industrial applications. When injected into the cooling water circuits of electric power stations or industrial plants, on-site generated sodium hypochlorite provides efficient protection to the equipment against the growth of micro and macro organic fouling. This occurs without the undesirable side effects of commercial hypochlorite, such as the build-up of hard deposits by reaction of excess alkalinity with the substances dissolved in water or the safety hazard connected with the transportation, storage and handling of chlorine gas. The technology eliminates dependency on outside suppliers and the heavy costs of purchased commercial products.

Features & Benefitstures & Benefits

System Specifications

| Model | GTH-1000 | GTH-2000 | GTH-5000 | GTH-10000 | GTH-20000 | GTH-40000 |

| Available chlorine(kg/h) | 1 | 2 | 5 | 10 | 20 | 40 |

| NaClO Output flow(L/h) | 500 | 1,000 | 2,500 | 5,000 | 10,000 | 20,000 |

| NaClO concentration(mg/L) | 2,000 | 2,000 | 2,000 | 2,000 | 2,000 | 2,000 |

| Power supply(kw) | 6 | 12 | 30 | 60 | 120 | 240 |

| Voltage | 380V/50hz three phase | 380V/50hz three phase | 380V/50hz three phase | 380V/50hz three phase | 380V/50hz three phase | 380V/50hz three phase |

| Additive | 2.5~3% | 2.5~3% | 2.5~3% | 2.5~3% | 2.5~3% | 2.5~3% |

| Feed water flow (L/h) | 500 | 1,000 | 2,500 | 5,000 | 10,000 | 20,000 |

| Salt Consumption | 3.5kg/kg Cl2 | 3.5kg/kg Cl2 | 3.5kg/kg Cl2 | 3.5kg/kg Cl2 | 3.5kg/kg Cl2 | 3.5kg/kg Cl2 |

| Power consumption | 5kw/kg Cl2 | 5kw/kg Cl2 | 5kw/kg Cl2 | 5kw/kg Cl2 | 5kw/kg Cl2 | 5kw/kg Cl2 |

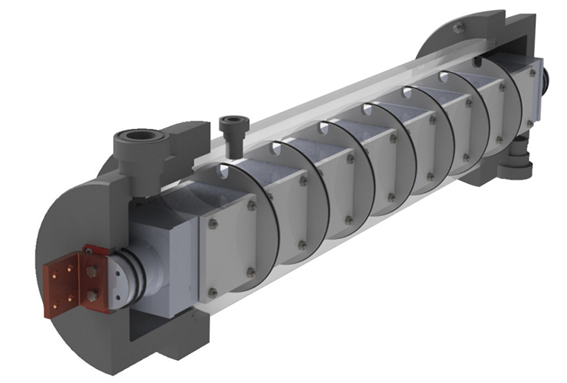

| Cell arrangement | Horizontal | Horizontal | Horizontal | Horizontal | Horizontal | Horizontal |

| H2 production amount | 0.35m3/kg Cl2 | 0.35m3/kg Cl2 | 0.35m3/kg Cl2 | 0.35m3/kg Cl2 | 0.35m3/kg Cl2 | 0.35m3/kg Cl2 |

| Number of Cell | 1 pcs | 2 pcs | 2pcs | 2pcs | 4pcs | 4pcs |

| Operation pressure | 2~4bar | 2~4bar | 2~4bar | 2~4bar | 2~4bar | 2~4bar |

| Feed water temperature | 15~25℃ | 15~25℃ | 15~25℃ | 15~25℃ | 15~25℃ | 15~25℃ |

| Cleaning mode | Acid washing | Acid washing | Acid washing | Acid washing | Acid washing | Acid washing |

Application

-