800g/h 0.8% Salt Water Electrolysis Sodium Hypochlorite Generator for Swimming Pool

The Purevita sodium hypochlorite generator generates a 0.8 % sodium hypochlorite solution through the electrolysis of brine, consuming only water, salt and electricity. By producing hypochlorite on-site and on-demand, the system eliminates concerns associated with transportation and storage of chlorine gas or commercial sodium hypochlorite solutions, making it ideal for any medium to large scale application requiring chlorination.

Capacity:

800g/hOutput Flow:

125L/hControl:

PLC controlChlorine concentration:

5000~8000ppmAdditive:

Food Grade SaltSalt Consumption:

3.5kg/kg Cl2Power Consumption:

4.5kw/kw Cl2Application:

Drinking water plant, waste water plant, swimming pool, etc800g/h 0.8% Salt Water Electrolysis Sodium Hypochlorite Generator for Swimming Pool

Brief Introduction

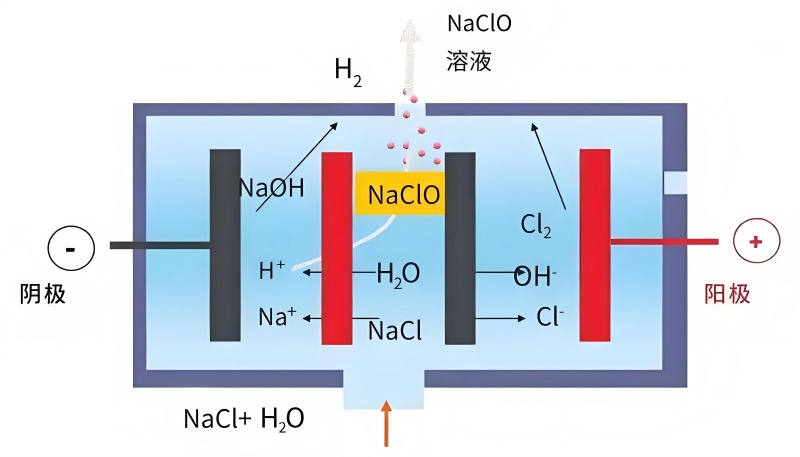

Saline solution contains the several kinds of ions such as Na +, H -, when electrolysis, under a certain voltage, as a result of the movement of ions in the electrolyte solution and electrode reaction, the conductive effect occurs, then CL -, OH - such as negative ion to the anode, and positive ions such as Na +, H + to the cathode, and the corresponding electrode discharge occurs, thus carries on the REDOX reaction, the corresponding material production.

Electrode reaction:

anode: 2Cl- - 2e → Cl2;

cathode: 2H+ + 2e → H2;

Solution reaction:

2NaOH + Cl2 → NaCl + NaClO + H2O

Overall reaction as follow:

Na Cl + H2O + DC →NaClO + H2↑

Advantage of Purevita Sodium Hypochlorite Generator

Specifications:

| Model | GTS-100 | GTS-200 | GTS-300 | GTS-400 | GTS--500 |

| Dimension of Host Machine | 720*750*1850mm | 720*750*1850mm | 720*750*1850mm | 720*750*1850mm | 720*750*1850mm |

| Available chlorine | 100g/h | 200g/h | 300g/h | 400g/h | 500g/h |

| NaClO Output flow | 20L/h | 40L/h | 60L/h | 80L/h | 100L/h |

| NaClO concentration | 5000ppm | 5000ppm | 5000ppm | 5000ppm | 5000ppm |

| Power supply | 1kw | 2kw | 2kw | 3kw | 3kw |

| Voltage | 220V/50hz single phase | 220V/50hz single phase | 220V/50hz single phase | 220V/50hz single phase | 220V/50hz single phase |

| Feed brine concentration | 2.5~3% | 2.5~3% | 2.5~3% | 2.5~3% | 2.5~3% |

| Feed Salt requirement | Food grade salt | Food grade salt | Food grade salt | Food grade saltF | Food grade salt |

| Feed water flow | 20L/h | 40L/h | 60L/h | 80L/h | 100L/h |

| Feed water requirement | tap water | tap water | tap water | tap water | tap water |

| Salt Consumption | 3.5kg/kg Cl2 | 3.5kg/kg Cl2 | 3.5kg/kg Cl2 | 3.5kg/kg Cl2 | 3.5kg/kg Cl2 |

| Power consumption | 4.5kw/kg Cl2 | 4.5kw/kg Cl2 | 4.5kw/kg Cl2 | 4.5kw/kg Cl2 | 4.5kw/kg Cl2 |

| Cell arrangement | Vertical | Vertical | Vertical | Vertical | Vertical |