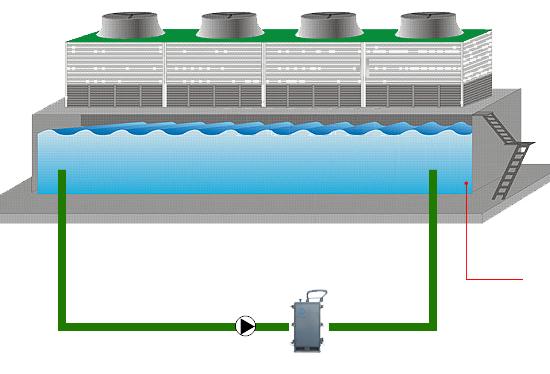

Electrochemical Recirculating Water Treatment System for Cooling Tower

Electrochemical Recirculating Water Treatment System not only has the anti scaling, sterilization, algae killing, corrosion inhibition and other properties that can be achieved by chemical circulating water treatment, but also has functions such as scale removal, scale dissolution, and degradation of organic substances, thereby achieving the effects of increasing concentration ratio, reducing emissions, saving water and electricity in an environmentally friendly manner.

Electrochemical Recirculating Water Treatment System for Cooling Tower

Theoretical Basis

The theoretical basis of electrochemical recirculating water treatment equipment of Purevita is electrolysis theory and polarmolecular theory. Under the action of direct current, the positive and negativeions in the aqueous solution between the positive and negative plates will move to the polar opposite plate,resulting in electron gain and loss reaction (i.e.,discharge reaction).

After anti scaling, descaling and preventing new scale, old scale will become loose and soft scale, gradually falls off, and hard scale will be removed.

Sterilization and algae removal of organic matter in the water to inhibit the growth of bacteria and algae

Corrosion inhibition and corrosion prevention:

Fe2 +20H-=Fe(OH),is oxidized into Fe,0 -nH,0 (red rust),Fe,O -H,O reacts withelectrons to form Fe 0,(magnet), and Fe Owill separate the steel pipe wall from thewater.

-

Three Major Problems Recirculating Water

-

Comparative Advantges to Chemical

| Analyze the specific content | Chemical method | FEC electrochemical method |

| Theory | Chemical theory | Electrolysis theory and physical adsorption theory |

| Investment expense | The early investment is high,and the follow-up něeds long-term high investment |

Initial investment is high,and there is no subsequent investment |

| Equipment maintenance cost | Perennial maintenance,high cost | No routine maintenance and low cost |

| Daily operation and maintenance | Complex and specialized skills are required | Operation and maintenance are very simple |

| Scale impurity | Still in circulating water | Remove the scale as a solid |

| Concentration ratio | less than 3 times | 6-9 times |

| Sewage treatment cost | Higher | Zero |

| Corrosion of pipes and equipment | Strong corrosion | No corrosion |

| Cleaning of circulating water system | Regular cleaning is required | No regular cleaning |

| Pollutant discharge | Regular discharge is required whěn the reagent is saturated |

There is no chemical,and the drainage is reduced by 20%-60% |

| Environmental pollution | High secondary pollution | No secondary pollution |

| Whether the scaling system can be treated | Unable to handle (need to disassemble the system for cleaning) |

It can restore the pipe blocked |

Effect of water treatment |

Unstable,and the technical demand is very high |

Stable and real-time monitoring |

| Equipment Model | FEC-A3000 | FEC-A5000 | FEC-A8000 | FEC-A10000 | FEC-A12000 | FEC-A15000 |

| Equipment Dimensions:L*W*H(cm) | 267x163x230 | 267x163x230 | 322x163x235 | 322x163x235 | 377x163x240 | 435x163x250 |

| Weight(kg) | 4000 | 4000 | 5000 | 5000 | 6000 | 7000 |

| Working Pressure(bar) | 0 | 0 | 0 | 0 | 0 | 0 |

| Design Life of Equipment(years) | 20 | 20 | 20 | 20 | 20 | 20 |

| Operating Temperature(℃) | 1~95 | 1~95 | 1~95 | 1~95 | 1~95 | 1~95 |

| Inlet Diameter(mm) | DN150 | DN150 | DN150 | DN150 | DN150 | DN150 |

| Bypass filtration coefficient | 1~3% | 1~3% | 1~3% | 1~3% | 1~3% | 1~3% |

| Max recirculating water(m³/h) (depending on waterquality) |

3000 | 5000 | 8000 | 10000 | 12000 | 15000 |

| Average operating power(KW) | 7~12 | 10~16 |

12~18 | 14~20 | 17~25 |

20~30 |

| DC power supply | 800A:24V | 1200A:24V | 1500A:24V | 2000A:24V | 2400A:24V | 3000A:24V |