Ozone Capacity:

2kg/hOzone Concentration:

25mg/LAir Flow:

81Nm3/hAir Source:

AirPower Consumption:

16-18 kwh/kg O3Cooling Water Volume:

≤8m3/hExhaust Destroyer for Ozone Generator

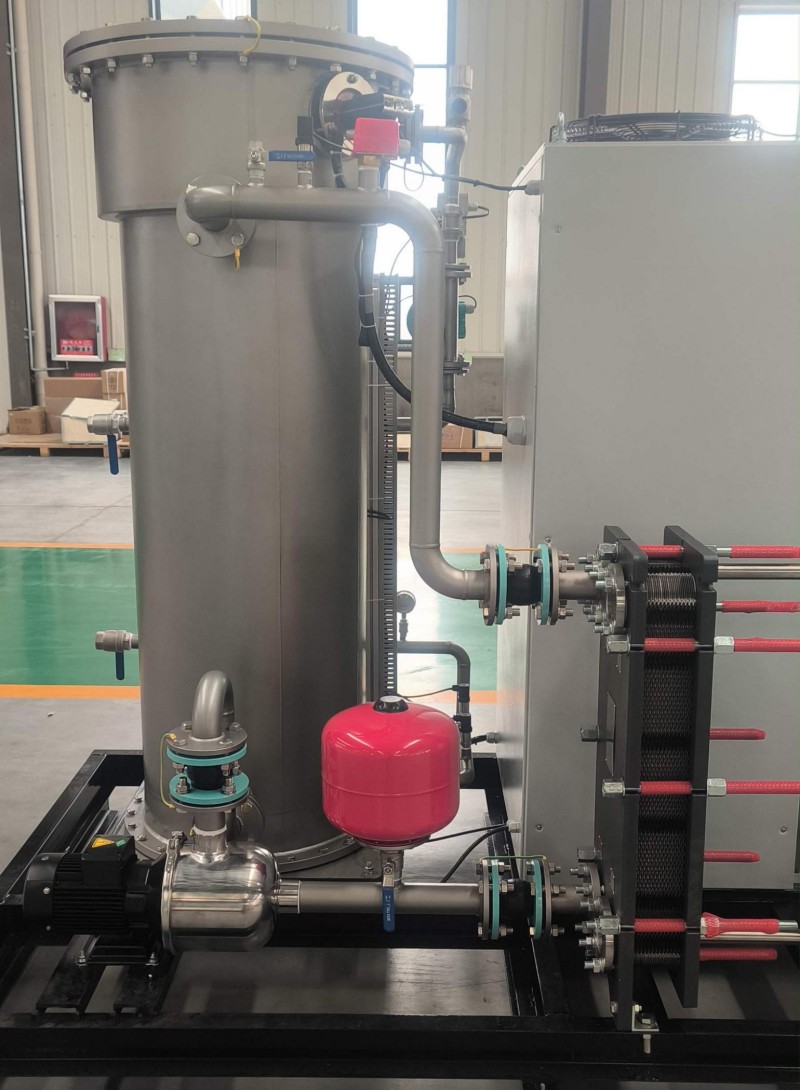

Brief Introduction

Mist Eliminator

Its main role is to remove finedroplets (fog droplets) from theexhaust gases in order to preventthese droplets from entering thesubsequent treatment unit orbeing discharged into theatmosphere.

Gas-Liquid Separator

Its main function is to separate the steam and liquid moisture in the tail gas to ensure that the gas entering the reactor is dry, so asto optimize the reaction conditions and improve the treatment efficiency.